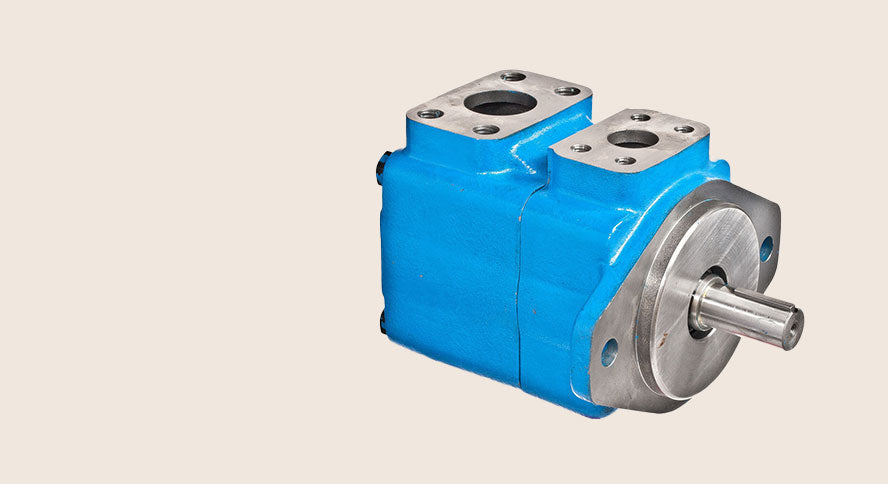

The Vickers vane pump, a staple in hydraulic systems, is known for its reliability, efficiency, and robust design. Developed by Vickers Inc., this pump plays a critical role in various industrial applications, including manufacturing, automotive, and aerospace sectors. This article delves into the working principles, types, applications, and advantages of the Vickers vane pump.

Working Principles

The Vickers Vane Pump operates on the principle of positive displacement. It consists of a rotor, vanes, and a cam ring. Here’s a step-by-step breakdown of its operation:

1. Rotor and Vanes: The rotor is centrally mounted and houses several vanes that can slide in and out. As the rotor spins, centrifugal force pushes the vanes against the inner surface of the cam ring.

2. Cam Ring: The cam ring is eccentric to the rotor, creating varying volumes between the vanes and the ring.

3. Intake and Compression: As the rotor turns, the volume between the vanes and the cam ring increases on one side, drawing hydraulic fluid into the pump (intake phase). On the opposite side, the volume decreases, compressing the fluid and forcing it out through the discharge port (compression phase).

This continuous cycle ensures a steady flow of hydraulic fluid, making the Vickers vane pump highly efficient.

Types of Vickers Vane Pumps

Vickers vane pumps come in several types, each designed to meet specific needs:

1. Single Vane Pumps: These have a single set of vanes and are typically used in low to medium-pressure applications.

2. Double Vane Pumps: Featuring two sets of vanes, these pumps provide higher flow rates and are suitable for medium to high-pressure applications.

3. Variable Displacement Vane Pumps: These pumps can adjust the volume of fluid they displace, making them ideal for applications requiring varying flow rates.

Applications

The versatility of Vickers vane pumps makes them suitable for a wide range of applications:

1. Industrial Machinery: Used in hydraulic presses, injection molding machines, and other industrial equipment where consistent fluid pressure is crucial.

2. Automotive: Employed in power steering systems and automatic transmissions.

3. Aerospace: Utilized in aircraft hydraulic systems for their reliability and ability to operate under high pressure.

4. Marine: Found in steering systems and deck machinery on ships.

Advantages

The Vickers vane pump offers several advantages that make it a preferred choice in various industries: Check out: Directional Control Valve

1. High Efficiency: The positive displacement mechanism ensures consistent and efficient fluid flow.

2. Durability: Built to withstand harsh operating conditions, these pumps have a long service life.

3. Quiet Operation: The design of the vane pump results in relatively quiet operation compared to other types of hydraulic pumps.

4. Ease of Maintenance: Vickers vane pumps are designed for easy disassembly and reassembly, simplifying maintenance and repair tasks.

5. Flexibility: Available in various configurations, they can be tailored to meet specific application requirements.

Conclusion

The Vickers vane pump is a testament to engineering excellence, offering reliability, efficiency, and versatility across multiple industries. Its robust design and consistent performance make it a vital component in hydraulic systems worldwide. Whether in industrial machinery, automotive, aerospace, or marine applications, the Vickers vane pump continues to be a cornerstone of hydraulic technology.

Comments on “Vickers Vane Pump: A Comprehensive Guide | TECH-UX”